Backflow Prevention, Cross Connection Control, and the Environmental Operators Certification Program

By Kalpna Solanki CPHI(C) BSc MBA

What is Cross Connection Control?

Cross Connection Control processes are to prevent contamination of potable water as a result of backflow through pipe cross connections. Whilst the terms are often used interchangeably, all Backflow Prevention is part of Cross Connection Control, but the reverse is not the same. For example, in many labs, we would often see rubber tubes dangling from taps into the sink to prevent splashing, and sometimes these tubes would be immersed in a beaker with chemical solutions. This has now resulted in a cross connection. Having no tube or a short tube results in an air gap preventing backflow. Of course, having a backflow prevention device in place is the ultimate method for preventing the foibles of undergrad science students who sometimes do things they should not.

But what exactly is backflow?

Backflow

Backflow is the undesired reversal of flow from a building or facility back into the drinking water system that is caused by either back siphonage or back pressure:

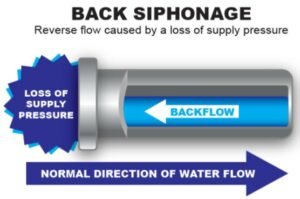

- Back siphonage occurs when there is a partial vacuum in the drinking water system from large water use events such as a watermain break or firefighting activities. This vacuum may draw contaminated water back into the drinking water system.

Figure 1: Back Siphonage (Source: City of Durham)

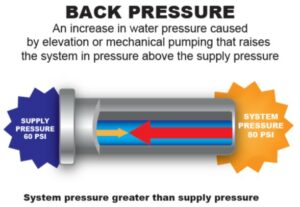

- Back pressure occurs when there is a connection to a non-potable water supply operating at a higher pressure than the drinking water system. Back pressure can be created by booster pumps, temperature increases in boilers, or elevated piping. This increased pressure may push contaminated water back into the drinking water system.

Figure 2: Back Pressure (Source: City of Durham)

So, tell me again, why is this important?

Backflow events have the potential to contaminate the water in our drinking water distribution system, which can cause implications for human health and safety. Canada has a history of backflow incidents highlighting the importance of backflow prevention programs. Some examples:

2011: An Oakville ON high school had to be closed due to cleaning chemicals entering its water lines. A backflow device successfully prevented any impact to the local drinking water supply.

2005: Stratford, ON residents discovered pink tap water following a backflow event at a local car wash. Residents of Stratford went without water for two days.

2002: An Edmonton high rise had blue caustic water flowing from the taps. The cause was backflow from the heating system after repairs to internal water lines. The issue took two weeks to correct.

1997: In Guelph, ON, petroleum chemicals back siphoned from an industry into the drinking water system impacting 50,000 residents.

1989: In Edmonton, AB, staff at the laboratory and offices of a research facility in noticed a smell coming from the hot water at the facility. A growth nutrient for microorganisms had backflowed from the laboratory into the facility’s domestic hot water system. The potable water system at the facility needed to be chlorinated and flushed.

There is also a notable incident from the US from 1983: In Woodsboro, MD, Paraquat, a highly toxic pesticide, held in storage tanks connected to a town water supply caused the drinking water for 63 homes to be contaminated.

These are the events we know of. There have likely been hundreds if not thousands of similar events that we don’t even know about because the impacts of the backflow were not as severe.

But surely, this is preventable?

Absolutely – ALL of the aforementioned incidents could have been prevented. Backflow can be prevented through backflow prevention devices. These devices allow water to flow only in one direction, hence preventing backflow and contamination of water supplies from external sources.

Figure 3: Backflow Preventer from a Commercial Facility (Source: Watts)

Simply installing a backflow preventer is not enough, however. To ensure the device works in the manner it is supposed to, it needs routine testing (at least annually), and repair/replacement when necessary.

This is obviously important…so there must be federal, provincial, or territorial regulations mandating the installation, testing, and maintenance of backflow prevention devices. Correct?

Therein lies the problem. Backflow prevention is in the public interest, yet there is no such regulation in place federally, in British Columbia, or in Yukon. Instead, within BC and YK, there are some municipalities with bylaws that mandate backflow prevention devices, and sometimes even mandate that they get tested on an annual basis. These backflow prevention assembly testers can obtain voluntary certification through an entity approved by the municipality.

So, what does this have to do with the EOCP, and Environmental Operators?

Whilst there is no entity named in legislation as being responsible for overseeing certification related to Backflow Prevention and Cross Connection Control in British Columbia or Yukon, logic would dictate that the EOCP oversees this.

The EOCP is named in legislation in BC and YK as the organization responsible for many aspects related to safe drinking water and wastewater management:

- The Drinking Water Protection Regulations (BC)

- The Municipal Wastewater Regulations (BC)

- The Public Health and Safety Act (YK)

Thus, the EOCP, as of mid-2024 will be offering Backflow Prevention Assembly Tester and Cross Connection Control Inspector certification.

What will this look like?

We have worked with Subject Matter Experts to assemble a robust process for the training and certification of professionals who work in the area of Backflow Prevention and Cross Connection Control. Similar to other certifications offered through the EOCP, this new program will consist of:

- Need to Know* criteria outlining the necessary job tasks;

- Courses* need to follow the NTK criteria;

- Upon completion of the course, a practical exam will be administered by the training provider;

- A written exam, with a fee of $150, comprising of 100 questions, will need to be completed within a time period of three hours. The exam will have a pass grade of 70% and will be available in web-based, paper, and oral formats;

- To maintain certification, 1.2 CEUs will need to be completed in every two-year reporting period.

* the NTK criteria and training will be based on the ‘AWWA Canadian Cross-Connection Control Manual’

What about reciprocity and membership dues?

As with the EOCP’s current process, individuals certified with acceptable valid certifications from other organizations or jurisdictions will be granted an equivalent certification by the EOCP. Along with that, as is the current process, regardless of the number of certifications one holds, there is one annual membership fee. So, if you are a WT, WD, WWC, and/or WWT Operator, this would be an additional certification that would be available to you at no cost to you, or your organization.

All of this sounds great, but why?

This is an area that many in the industry, as well as the EOCP directors and staff, have had concerns about for several years. We believe that with our expertise in the water and wastewater sector going all the way back to 1966, the EOCP is well-positioned to administer this program. This is what we do best…we examine and certify professionals who work in the water and wastewater industry. We believe this is in the public interest.